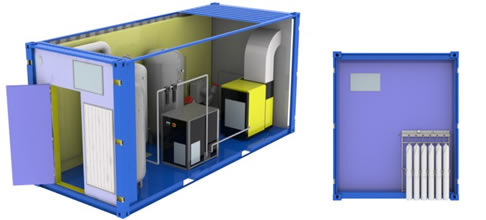

Mobile oxygen filling station

Mobile oxygen filling station is oxygen filling system built in ISO container. The oxygen is produced from compressed air by pressure swing adsorbtion technology. The compressed air system as well as the separation system is integrated in the container. The high pressure ramp for bottle filling is placed at the backside of the container.

Features:

The surveillance system and audio visual alarms are optional.

| Technical specification: | |||

| Model: | MOFS 4 | MOFS 8 | MOFS 16 |

| Capacity: | 3.2 m3/h | 6.4 m3/h | 16.0 m3/h |

| Operating conditions: | -20°C to 40°C | -20°C to 40°C | -20°C to 40°C |

| ISO container | 10ft. | 20ft. | 20ft. |

| Dimensions: | 3.1x2.5x2.6m | 6.1x2.5x2.6m | 6.1x2.5x2.6m |

| Weight: | 2100kg | 3700kg | 4600kg |

| Power: | 5.6kW | 14kW | 25kW |

| Filling capacity per 24h: | 12.8 cylinders | 25.6 cylinders | 64 cylinders |

The unit designed for high ambient temperatures is furnished with container insulation and air conditioning; the surface is treated with special coating.

| Model: | MOFS 4+ | MOFS 8+ | MOFS 16+ |

| Capacity: | 3.2 m3/h | 6.4 m3/h | 16.0 m3/h |

| Operating conditions: | -20°C to 50°C | -20°C to 50°C | -20°C to 50°C |

| ISO container | 10ft. | 20ft. | 20ft. |

| Dimensions: | 3.1x2.5x2.6m | 6.1x2.5x2.6m | 6.1x2.5x2.6m |

| Weight: | xykg | xykg | xykg |

| Power: | xykW | xykW | xykW |

| Insulation: |  |

|

|

| Air-conditioning: |  |

|

|

| Special coating: |  |

|

|

| Filling capacity per 24h: | 12.8 cylinders | 25.6 cylinders | 64 cylinders |

Mobile oxygen filling station is preferred compact solution design for outdoors ready to fill bottles with oxygen when and where needed.

Oxygen generator

Oxygen generator

Oxygen filling station

Oxygen filling station

Mobile oxygen production plant

Mobile oxygen production plant